Recycled Materials in IMDS: From Data Transparency to Sustainable Compliance

In the race toward a greener and more responsible automotive industry, the use of recycled materials has shifted from a “nice-to-have” to a regulatory and strategic necessity. As regulations tighten and sustainability expectations rise, automotive manufacturers and suppliers are turning to the International Material Data System (IMDS) to ensure transparency and compliance across the supply chain.

Let’s explore how recycled materials are classified and managed within IMDS, and why this matters more than ever for achieving environmental and legal targets.

I. Why Recycled Materials Are Increasingly Important in Automotive

Automotive manufacturers are under mounting pressure to reduce environmental impact. Regulatory bodies, especially in the European Union, have introduced stringent targets to increase the use of recycled materials and reduce landfill waste.

Notable examples include:

- EU End-of-Life Vehicles (ELV) Directive: Requires that 95% of a vehicle's mass be reused or recycled.

- EU 2030 target: Mandates that vehicles include at least 25% recycled plastic content, with a portion derived specifically from end-of-life vehicles.

Beyond regulation, the adoption of recycled content also supports brand reputation, reduces dependency on virgin raw materials, and contributes to circular economy goals—all critical elements in today’s sustainability-driven marketplace.

II. How IMDS Classifies Recycled Materials

IMDS helps companies track and declare material content throughout the automotive supply chain. One of its key features is the ability to distinguish between different types of recycled materials:

- Post-Industrial Recycled (PIR):

These are waste materials generated during the manufacturing process—such as plastic trimmings or metal shavings. PIR is usually clean and consistent, making it relatively easy to reintroduce into production.

- Post-Consumer Recycled (PCR):

These materials come from products that have reached the end of their life cycle, like old car parts, plastic packaging, or electronics. PCR materials require more extensive processing (e.g., cleaning, sorting) and may show greater variation in quality and composition.

By distinguishing between PIR and PCR in IMDS, manufacturers can offer greater transparency and better evaluate the performance and risk associated with recycled inputs.

III. Recycling Methods Recognized in IMDS

IMDS also considers the recycling process used to recover materials. Understanding the method is essential for assessing the quality and traceability of recycled content:

- Mechanical Recycling

This is the physical breakdown of waste into smaller parts (flakes, pellets) for reuse. PIR is ideal for mechanical recycling due to its homogeneity, while PCR may need significant preprocessing to achieve usable quality.

- Chemical Recycling

A more advanced process that uses chemical reactions to convert plastic waste into basic building blocks (e.g., monomers). Chemical recycling can transform mixed or contaminated PCR into virgin-quality material, enabling circularity even for complex waste streams.

Including the correct recycling method in IMDS entries ensures a realistic evaluation of recycled material quality and lifecycle impact.

IV. The Role of IMDS in Transparency and Compliance

One of IMDS’s core strengths lies in enhancing supply chain transparency. With proper usage, manufacturers and suppliers can:

- Declare the type, source, and percentage of recycled content.

- Ensure traceability of recycled material origin and processing.

- Promote responsible sourcing, particularly for PCR that may involve social and environmental risks.

- Prove compliance with EU ELV, REACH, RoHS, and other global regulations.

This level of detail supports both internal sustainability tracking and external audits, allowing companies to communicate their environmental responsibility with confidence.

V. IMDS Recommendation 025: Key Guidance for Recycled and Bio-Based Content

A significant tool for managing recycled content in IMDS is Recommendation 025, which provides structured guidance for recycled and bio-based material declarations.

Highlights from the latest revision include:

- Inclusion of bio-based content in material classification 7.1.

- Updated rules for mechanical recyclate thresholds and consistency checks.

- Alignment with ISO 14021:2016, especially for defining "recovered" or "reclaimed" material.

- Tables and examples that clarify how to calculate and declare recycled content—particularly for complex materials like polymers and steel.

These updates reflect the evolving expectations of regulators, OEMs, and consumers alike. Suppliers are strongly encouraged to stay updated and align their practices with IMDS 025 to avoid reporting errors and ensure full compliance.

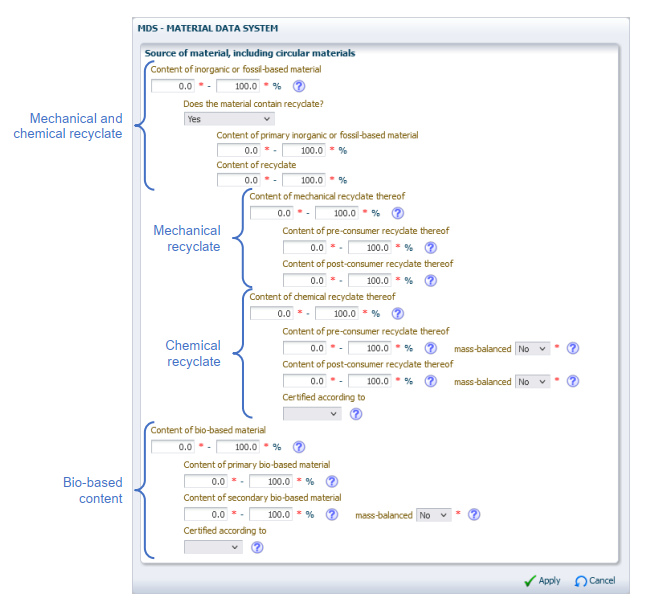

Figure 1: Evaluate the recycled and bio-based content of materials in IMDS system

Conclusion

Recycled materials are no longer optional in today’s automotive ecosystem—they are essential for compliance, innovation, and sustainable leadership. By using IMDS effectively, manufacturers can:

- Track recycled material accurately,

- Ensure regulatory compliance,

- Strengthen transparency across the value chain,

- And contribute meaningfully to the global circular economy.

At Vinso, we specialize in materials compliance and IMDS reporting. If you need help navigating recycled content requirements, interpreting IMDS Recommendation 025, or aligning with EU directives, our team is here to support you.

Contact us today to streamline your compliance process and stay ahead in sustainability by email: info@vinsoglobal.com